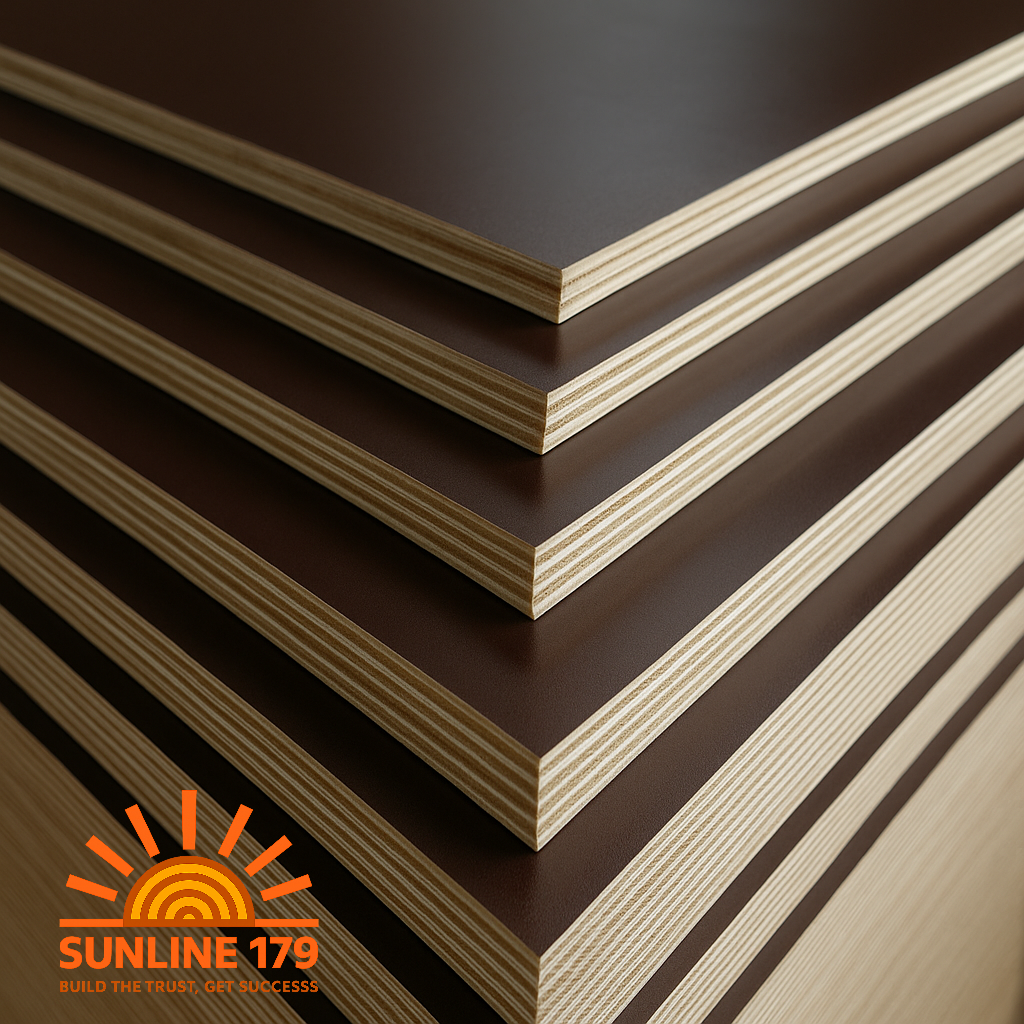

🔹 1. Core Specifications – Engineered for Contractors

Glue: Phenolic 72 hours

Core: Eucalyptus

Face/Back: Dynea film

Size: 1220 × 2440 mm / 1250 × 2500 mm

Thickness: 9 / 12 / 15 / 18 / 21 mm

Tolerance: ±0.3 mm

Reuse times: 50 reused times

Packing: Export standard

🔹 2. What Makes Sunline 179 Different

✔ Smooth phenolic-film surface — fast demolding, no concrete adhesion

✔ Stable hardwood core — high-pressure hot press — reduced warping

✔ Waterproof edge coating — extended outdoor lifespan

✔ Optimized weight — easy installation — labor-saving

✔ 100% QC control for every batch and every container

🔹 3. Key Applications

• Floor, beam, slab, and wall formwork

Ensures flat concrete surfaces with no plastering required.

• High-rise, infrastructure, and bridge projects

Designed for high load-bearing capacity and long-term durability in humid environments.

• International construction projects

Fully compliant with the most rigorous technical standards.

🔹 4. Benefits for Contractors & Partners

-

Reduce formwork costs by 15–25% thanks to multiple reuse cycles

-

Ensure project timelines — lightweight & fast installation

-

Stable, container-consistent quality — minimizing construction risks

-

Transparent service — QC photos, videos, and container tracking included

🔥 Message from Sunline 179

We don’t just sell plywood —

We deliver a complete formwork solution that helps contractors cut costs and improve project performance.

SUNLINE 179 – BUIL THE TRUST, ACHIEVE SUCCESS.

Trust is built from real quality and real commitment.